- This guide describes all the main methods of removing a locking wheel nut and bolt without using the key. This guide also describes how to replace your lost locking wheel nut key if you don't fancy using these methods. It describes methods for both of the common types of locking wheel nuts and bolts ("Spinning Collar" like McGard, "Shear Head" like Citroen and Peugeot, and "Standard" keyed bolts).

- We recently bought a new car and (surprise, surprise!) there was no key for the locking wheel bolts. As the MOT approached there was no option but to remove the offending locking wheel bolts.

- Over the years I have gone through just about every possible way of doing this, so here below are the various methods for removing a locking wheel bolt without a key... the ones that work well, and those that require you to be lucky. Locking nuts can be easier to remove than locking bolts and if you have the clearance a nut splitter is a simple and effective approach. However, normally you don't get so lucky.

- If you don't fancy using any of the methods detailed in the sections below to remove your locking wheel nuts and bolts without a key, then you can always just replace the lost or broken locking wheel nut key. Sometimes the easiest way to remove locking wheel nuts is to buy a replacement key. You can have your key identified by your dealer (it's ID number or key code is also sometimes listed at the back of your service booklet). Up until recently this was your only sure fire option of replacing the key.... but now you have another option, just take a photo!

-

Recently (February 2016) I was contacted by a company (www.lockingwheelnutkeys.co.uk) offering a worldwide service to identify and replace lost locking wheel nut and bolt keys using just a photo of the locking bolt left in the wheel - all for for £38 + P&P (at the time of writing). Now that seemed like a brilliant idea...if it worked. So I offered to test the service and you can find my full review of it by clicking here. Let me be clear, these guys haven't paid me for the review, nor am I connected to them in any way - I was just very impressed by their business and thought it might help others. From my experience all you have to do is take a photo of the locking bolt left in your wheel and they'll find the right key!

Recently (February 2016) I was contacted by a company (www.lockingwheelnutkeys.co.uk) offering a worldwide service to identify and replace lost locking wheel nut and bolt keys using just a photo of the locking bolt left in the wheel - all for for £38 + P&P (at the time of writing). Now that seemed like a brilliant idea...if it worked. So I offered to test the service and you can find my full review of it by clicking here. Let me be clear, these guys haven't paid me for the review, nor am I connected to them in any way - I was just very impressed by their business and thought it might help others. From my experience all you have to do is take a photo of the locking bolt left in your wheel and they'll find the right key! - Anyway, read the review of their service first, but given that you could have a replacement locking wheel nut key from them within 24hrs for around £55 total if you use their "Next Working Day" service (or for much cheaper if you are willing to wait), why would anyone call on the RAC, AA or some other expensive professional to remove their locking bolts and then have to pay for new ones?

- There are three types of locking wheel nut and bolt available and the methods you need to use to remove them are different in each case.

The standard type is a simple bolt or nut with a keyed face - most cars have this type fitted.

The standard type is a simple bolt or nut with a keyed face - most cars have this type fitted. - However, some locking wheel nuts and bolts have a rotating collar that is supposed to stop some of the standard removal procedures from working. The idea is that the collar 'spins' around the bolt or nut preventing any locking wheel nut removal tool from getting a grip. That's the idea anyway... however there are now many tools on the market that can remove these spinning collar locking bolts in seconds. This is one of the reasons I am not a fan of this type of locking nut or bolt. Opportunist theft of alloys is pretty much a thing of the past in the UK, but there are "Steal to Order" gangs around after the high end wheels. "Spinning Collar" locking bolts and nuts will not deter "Steal to Order" thieves, as these guys have the kit to remove them easily, but they will leave you with a potentially expensive headache if you lose the key. Believe me the only way to protect your expensive wheels is to lock the car up at night and avoid parking in dodgy areas - I say this because of experience!

Finally, we have the "shear head" locking bolt (see the photo to the right) that are commonly found on Citroen and Peugeot cars. I haven't had any experience of these, so I got in touch with a mate "in the trade" who is used to dealing with them. In his view they are without doubt the most annoying type of locking wheel nut for any car owner. These are designed to break by shearing off and leaving the body of the bolt behind if removal is attempted without the proper key. Great idea right? Well it would be if the bolts and their keys weren't apparently prone to general failure even if you use them as intended. When they fail they'll leave you with a potentially expensive headache, so the advice is that if you have this type of locking wheel nut on your car you should replace them as soon as you can with a more standard type.

Finally, we have the "shear head" locking bolt (see the photo to the right) that are commonly found on Citroen and Peugeot cars. I haven't had any experience of these, so I got in touch with a mate "in the trade" who is used to dealing with them. In his view they are without doubt the most annoying type of locking wheel nut for any car owner. These are designed to break by shearing off and leaving the body of the bolt behind if removal is attempted without the proper key. Great idea right? Well it would be if the bolts and their keys weren't apparently prone to general failure even if you use them as intended. When they fail they'll leave you with a potentially expensive headache, so the advice is that if you have this type of locking wheel nut on your car you should replace them as soon as you can with a more standard type. - Removing Standard Locking Wheel Nuts and Bolts (without a rotating or spinning collar)

- I would suggest you try the methods shown in the sections below in the following order: Method 1, Method 4, Method 2 (if you couldn't find a removal tool), and finally Method 3. There is one method, Method 5, which you should never attempt, leave this one to the professionals.

- Removing Rotating Ring or Spinning Collar Locking Wheel Nuts and Bolts (e.g. McGard)

- Method 2 in the sections below will not work for this type of locking wheel nut. Neither will chiseling or grinding off the spinning collar or ring, this will in fact make it more difficult to remove in most cases. Method 1 is unlikely to work, as this type of locking bolt or nut is usually an after-market purchase. The only sure fire ways of getting them off without damage to your wheels is to use Method 3 (don't believe the hype, you can easily weld to these types of bolt and nut) or Method 4. If you use Method 4, make sure you find a garage with the right kind of locking wheel nut removers that bore into the centre of the wheel bolt or nut (i.e. not tools 1 or 2 shown in Method 4 below as these will not work). The RAC and AA both have this kind of removal tool, as do most well kitted out garages. There is one method, Method 5, which you should never attempt, leave this one to the professionals.

- Removing "Shear Head" Locking Wheel Bolts (e.g. Citroen and Peugeot)

- Without doubt the most hassle free and cost effective way to remove these for the average car owner will be to purchase a new key from the dealer. Having said that, they are reasonably easy to remove with the right tools if you have them. The first step is usually to remove the shear head from the bolt (see photo in section above). The "Torx" approach shown in Method 2 will work in many cases once the shear head is removed from the bolt

. Using the "Socket" approach shown in Method 2 will remove the shear head but leave the bolt intact (although you may have issues removing the shear head from your socket!). Method 4 is the usual solution to removing this type of bolt, but you need the "Universal" kind of locking wheel nut remover that bores into the bolt (i.e. not tools 1 or 2 shown in Method 4 below as these will just shear off the bolt head). The RAC and AA both have this kind of removal tool, as do most well kitted out garages. Method 3 is not recommended as it is likely to result in damage to your wheels as this type of bolt is highly recessed. There is one method, Method 5, which you should never attempt, leave this one to the professionals. If you are really stuck there is one further technique that may help (thanks must go to Ray, a reader of this guide, for alerting me to this) - you can modify your wheel bolts to take another key if they are of the Citroen "pin" type (see the photo to the left above). This involves carefully redrilling each bolt to take the modified pin positions of the new key. If done accurately this should be successful, but you may need a professional to do this for you which could prove expensive.

. Using the "Socket" approach shown in Method 2 will remove the shear head but leave the bolt intact (although you may have issues removing the shear head from your socket!). Method 4 is the usual solution to removing this type of bolt, but you need the "Universal" kind of locking wheel nut remover that bores into the bolt (i.e. not tools 1 or 2 shown in Method 4 below as these will just shear off the bolt head). The RAC and AA both have this kind of removal tool, as do most well kitted out garages. Method 3 is not recommended as it is likely to result in damage to your wheels as this type of bolt is highly recessed. There is one method, Method 5, which you should never attempt, leave this one to the professionals. If you are really stuck there is one further technique that may help (thanks must go to Ray, a reader of this guide, for alerting me to this) - you can modify your wheel bolts to take another key if they are of the Citroen "pin" type (see the photo to the left above). This involves carefully redrilling each bolt to take the modified pin positions of the new key. If done accurately this should be successful, but you may need a professional to do this for you which could prove expensive. - Before you even think of trying any of the methods below, make very sure you really have lost the key. You will be able to get them off without it, but it is (sometimes) a much harder job. Also if you are going to try any of the approaches below, make sure you have some spare bolts to put back into the holes once you have removed the locking ones.

- If you don't want to try the methods below you can get replacement keys from various places. If you can wait 24hrs and want a replacement key give the guys at lockingwheelnutkeys.co.uk a go as they can get you a replacement key for most vehicles and trailers very quickly using just a photo from your phone (you can read my full review of their service by clicking here). Finally, you may be able to have your key identified by your dealer (it's ID number is also sometimes listed at the back of your service booklet). Whilst you can purchase a new key from your dealer, this can often work out more expensive than removing the old locking wheel nuts using one of the methods below and then just buying a new set of after-market locking wheel nuts. It will all depend on the brand of car you own.

- Method 1 - Find someone with the same locking wheel nuts or bolts

- This should always be your first port of call. First try the car dealer. Then bung some beer in the back of the car, swallow your pride and drive around the town looking for someone with the same car of exactly the same age and specification as yours parked in front of their house. If that doesn't work, try every garage. You are very unlikely to find a matching tool even if you strike it lucky as the wheel bolts are changed so often on models, but this is worth a try - if it pays off, hand them the beer. You should combine this approach with method 4 and hunt for a garage with a universal removal tool.

- Method 2 - Standard socket and a hammer or Torx, drill and hammer

Standard Socket and Hammer: Now I know this works as I've seen it done a few times, but you do risk wrecking a decent socket, also if your bolts are on very tight or are seized it will not work at all. Simply take a standard socket slightly smaller than the locking bolt or nut and hammer it on hard. The splines of the socket will bite into the locking bolt and should hold it tight. You should now be able to undo the locking bolt... if you are lucky! Always use a splined socket like those shown in the photo, others will not work... and before you ask, no this didn't get my locking bolts off and yes it was very difficult to remove the hammered on socket to try another technique. My advice would be only to use this technique if you have nothing else available.

Standard Socket and Hammer: Now I know this works as I've seen it done a few times, but you do risk wrecking a decent socket, also if your bolts are on very tight or are seized it will not work at all. Simply take a standard socket slightly smaller than the locking bolt or nut and hammer it on hard. The splines of the socket will bite into the locking bolt and should hold it tight. You should now be able to undo the locking bolt... if you are lucky! Always use a splined socket like those shown in the photo, others will not work... and before you ask, no this didn't get my locking bolts off and yes it was very difficult to remove the hammered on socket to try another technique. My advice would be only to use this technique if you have nothing else available. Torx, Drill and Hammer: This method can be useful if you have little or no clearance to hammer on a socket. However, think carefully before using it as it will prevent you from using the 'universal removal tool' described in Method 4. Because of this drawback and that fact that it is only successful occasionally I would only try this approach if you have no other option. To use this approach you need to have a large Torx or splined bit. This bit should be as large as possible and at least an T55 (11mm) Torx. You then drill a hole in the centre of the locking wheel bolt or nut (be careful) about the same size as the inner diameter of the Torx (i.e. without the splines, so 8mm for a T55 Torx) and as deep as possible (be careful with locking wheel nuts not to hit the threaded wheel stud). Finally, you hammer the Torx bit into the hole. The Torx splines will bite into the locking wheel bolt and you can then use the Torx to remove the bolt.

Torx, Drill and Hammer: This method can be useful if you have little or no clearance to hammer on a socket. However, think carefully before using it as it will prevent you from using the 'universal removal tool' described in Method 4. Because of this drawback and that fact that it is only successful occasionally I would only try this approach if you have no other option. To use this approach you need to have a large Torx or splined bit. This bit should be as large as possible and at least an T55 (11mm) Torx. You then drill a hole in the centre of the locking wheel bolt or nut (be careful) about the same size as the inner diameter of the Torx (i.e. without the splines, so 8mm for a T55 Torx) and as deep as possible (be careful with locking wheel nuts not to hit the threaded wheel stud). Finally, you hammer the Torx bit into the hole. The Torx splines will bite into the locking wheel bolt and you can then use the Torx to remove the bolt.

- Method 3 - Weld a bolt or socket to the locking wheel bolt or nut

- This works well but should be used as a last resort as you risk damaging your wheels and if you get it wrong you may well be left with a locking wheel bolt or nut that can only ever be drilled or ground out - a very, very expensive mistake! The basic idea is to weld a bolt to the end of the locking wheel bolt (make sure your bolt and locking bolt is steel first).

Make a really good strong weld with a MIG and cover your wheels so the alloys aren't splattered. Once you have them welded on there, you should be able to undo them with a normal socket. I'd always use a bolt (see photo) for this if you have locking wheel bolts rather than a socket or tube as if you mess up it is easier to get off and you may not have wrecked the locking bolt in the process so can try other techniques. However, for locking wheel nuts, a tube or spare socket should be placed over the nut and welded to it. Tubes and sockets can also be used with locking bolts and they may give a stronger joint than welding a bolt if you have the clearance to weld all the way round - if not drill holes in the side and weld into those. Done correctly this technique always works, but should only ever be used as a very last resort after methods 1, 2 and 4 have failed.

Make a really good strong weld with a MIG and cover your wheels so the alloys aren't splattered. Once you have them welded on there, you should be able to undo them with a normal socket. I'd always use a bolt (see photo) for this if you have locking wheel bolts rather than a socket or tube as if you mess up it is easier to get off and you may not have wrecked the locking bolt in the process so can try other techniques. However, for locking wheel nuts, a tube or spare socket should be placed over the nut and welded to it. Tubes and sockets can also be used with locking bolts and they may give a stronger joint than welding a bolt if you have the clearance to weld all the way round - if not drill holes in the side and weld into those. Done correctly this technique always works, but should only ever be used as a very last resort after methods 1, 2 and 4 have failed.

- Method 4 - Find or buy a locking wheel bolt or nut removal tool

This will work 99% of the time and is by far the easiest method. In fact it is as easy as if you had the proper key... but only if you have the right sort of removal tool. Now there are loads of different types of removal tool out there.

This will work 99% of the time and is by far the easiest method. In fact it is as easy as if you had the proper key... but only if you have the right sort of removal tool. Now there are loads of different types of removal tool out there.- The two most common, for "standard" (i.e. not spinning collars) wheel nuts, are shown in the photo. With these two types of tool you simply lock them onto a ratchet and as you try to undo the wheel bolt they "screw" themselves tightly onto it as they have left hand (reversed) threads/splines. However, beware as only removal tool No.1 will work 99% of the time. This tool has splines that bite into the locking bold and hold it very firmly as you 'undo' it. Removal tool No. 2 will work, but you need to get exactly (and I do mean exactly) the right size, also if your bolt is seized it will probably fail. Bottom line, do not be tempted by the removal tools you see in Halfords etc. buy a proper set or better still drive round the garages until you find someone who has one. If you need to buy a No. 1 tool you will find it is often listed as a "Bolt Extractor", which is exactly what it really is. This sort of tool pre-dates locking wheel nuts and has been tried and proven for years in garages for removing rounded off bolts, so I'm not sure why anyone bothered inventing the No. 2 type tool! Anyway, in the case of my new car, my comprehensive set of old tools (No. 2's) worked on 1 bolt, I found a garage with No. 1 type tools and had them all off in 10 mins and yes one was seized.

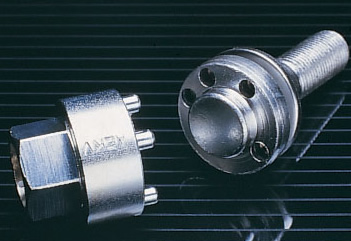

For "spinning collar" wheel nuts and bolts like McGard, you need a removal tool that will bore into the centre of the wheel nut or bolt (see photo on the right). These are far more expensive than the more standard type, but are "Universal" and will work on both standard and spinning collar wheel nuts and bolts. In addition, they will remove the "Shear Head" locking bolts found on Citroen and Peugeot either once the shear head has been removed or with an adapter that is included in the kit. This is why a lot of garages, the RAC and AA have them and use them. Because of the price of these tools it is probably not cost effective to buy one yourself (but it may be so check out the cost first). Often if you go to an independent garage and chat nicely to the guys they'll let you use them for free (always worked for me!). If they do, buy them a case of beer, it's nice to be nice and you never know when you might need them again. Never, ever go to a dealer or the RAC and AA if you can help it as these guys will charge you up to £20 a wheel to remove the bolts - which is daylight robbery for this very simple and quick job!

For "spinning collar" wheel nuts and bolts like McGard, you need a removal tool that will bore into the centre of the wheel nut or bolt (see photo on the right). These are far more expensive than the more standard type, but are "Universal" and will work on both standard and spinning collar wheel nuts and bolts. In addition, they will remove the "Shear Head" locking bolts found on Citroen and Peugeot either once the shear head has been removed or with an adapter that is included in the kit. This is why a lot of garages, the RAC and AA have them and use them. Because of the price of these tools it is probably not cost effective to buy one yourself (but it may be so check out the cost first). Often if you go to an independent garage and chat nicely to the guys they'll let you use them for free (always worked for me!). If they do, buy them a case of beer, it's nice to be nice and you never know when you might need them again. Never, ever go to a dealer or the RAC and AA if you can help it as these guys will charge you up to £20 a wheel to remove the bolts - which is daylight robbery for this very simple and quick job!

- Method 5 - Have the locking wheel bolts or nuts drilled or ground out.

Never try this method yourself always have a professional grind out your wheel nuts and bolts. This method will always work, but you are always going to end up with some damage to your wheels. If you try to do this yourself you may well end up with a ruined alloy wheel set, in the worst case you may end up with a structurally damaged and dangerous set of wheels. Even a professional will probably cosmetically damage your wheel set and while he'll get your locking wheel nuts off, he will charge you a fortune for the privilege. Finally, for locking wheel bolts, once you have ground down and removed the bolt head, you then have to find a way to remove the shaft which will be threaded into your wheel hub/disc assembly. If the thread is seized you will need to drill it out and then retap the bolt hole or replace the whole assembly. As a result, my personal recommendation is NEVER try this method unless there is no other solution, it may seem an obvious answer to your locking wheel bolt problems, but you will probably regret it if you decide to grind or drill them out!

Never try this method yourself always have a professional grind out your wheel nuts and bolts. This method will always work, but you are always going to end up with some damage to your wheels. If you try to do this yourself you may well end up with a ruined alloy wheel set, in the worst case you may end up with a structurally damaged and dangerous set of wheels. Even a professional will probably cosmetically damage your wheel set and while he'll get your locking wheel nuts off, he will charge you a fortune for the privilege. Finally, for locking wheel bolts, once you have ground down and removed the bolt head, you then have to find a way to remove the shaft which will be threaded into your wheel hub/disc assembly. If the thread is seized you will need to drill it out and then retap the bolt hole or replace the whole assembly. As a result, my personal recommendation is NEVER try this method unless there is no other solution, it may seem an obvious answer to your locking wheel bolt problems, but you will probably regret it if you decide to grind or drill them out!

It is only your donations that keep this website going. If we've helped you, please pay the favour forward and help others by keeping this content alive. You can do this by clicking here and donating. Thank you, for whatever you decide to give.

It is only your donations that keep this website going. If we've helped you, please pay the favour forward and help others by keeping this content alive. You can do this by clicking here and donating. Thank you, for whatever you decide to give.